To start with, securing an internship at BARC is not really easy, it being India’s premier research institute. So, I wasn’t expecting my call from there. But when I did come, I was out of my senses: overjoyed. I did not know what they took into consideration while selecting my profile; if it were my decent grades or the little research experience I had then while working in my professor’s laboratory. Or I don’t know what. Whatever it was, I was very very happy.

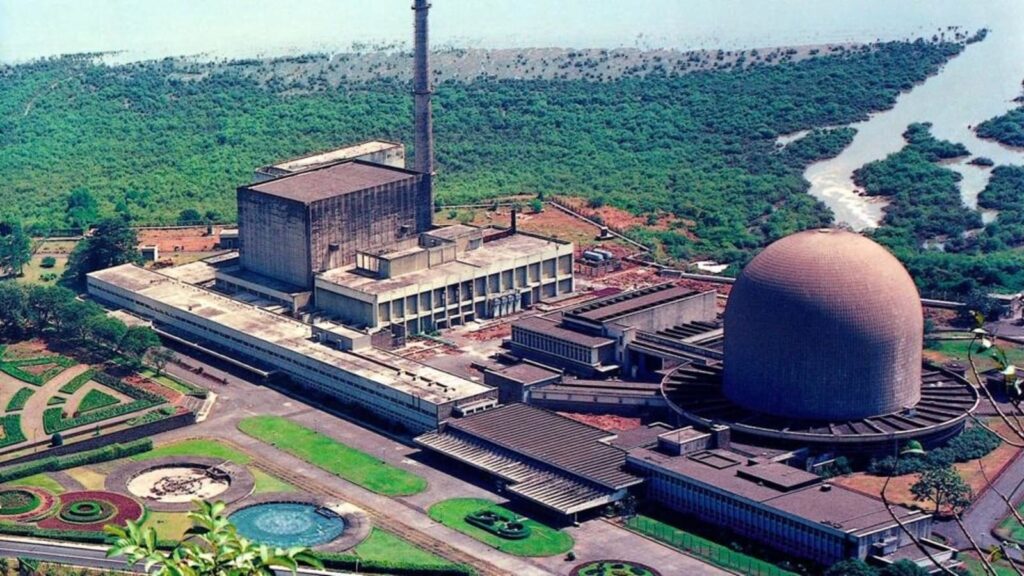

Arriving in Mumbai is in itself a story for anyone who has gone there at least once in their life. It is called the “City of Dreams”, and it sure was for me. Mumbai’s story is for another day, so I’ll tell you how BARC is special and what makes it one of the best research destinations in India.

The First Day was so different from all the internships I had done in the past. The scholarly environment was captivating. In subsequent days, it only became clear that it was going to be a different work experience. On regular days, the scientists working there gave an insight on how core research is conducted and ideas manifested on a platform before finally using them to make the required equipment. The most reflective learning that I took from BARC was that Engineering is much more than just solving lengthy equations and if brainstorming techniques are put to use effectively, it can open up new horizons to explore for designing products otherwise considered impossible to create. It was more a qualitative mind shift than anything else.

I had the opportunity to learn about a broad range of fields related to mechanical design and structural mechanics. By iterating designs of various components, I learned Design Conceptualization, while working in the testing lab gave me insights on how tests were performed and the collected data processed and analyzed by creating graphs of quantities such as stress and strain rates.

After returning back, some people on my research team even complimented me on how I viewed problems then as opposed to before the BARC Internship. The bond I built with my mentors (Junior Scientists) was so deep that we stay in touch even today.

Responsibilities

- Conceiving Design for various Mechanical parts used in the aerospace industry

- The problem statements would be given to us, and then we would be told to think of possible design solutions. First the concepts, then the sketches and finally CAD models, each step consisting of at least 3-3 iterations.

- Most of it was teamwork, and so brainstorming was a crucial part of the whole exercise. Every bit of it was fun, as teams competed with each other to provide the best design solution.

- Applied FEM to find numeric solutions for evaluating pressures & forces at various divisions of the reactor shell

- The best designs were then verified using EEM techniques for feasibility and strength computationally. Used tools were Ansys and FEAST.

- Executed High strain rate tests at the room as well as elevated temperatures on Split Hopkinson Pressure Bar (SHPB).

- After verification, real parts were tested by applying concepts of fracture mechanics using SHPB

- Measurement of Stress, Strains, Strain Rates and their interrelationships.

- Post-processing was done using statistical math. Data at various points were noted via placing sensors, and at various times, separated by continuous-time intervals.

Takeaways

- Design of new prototypes of components to bear high pneumatic pressure.

- Determination of force impact points in a pressure chamber using finite element method.

- Estimation of Stress v/s Strain curves for impact testing of SHPB.

- Recommended software for data compilation and drawing graphical curves such as MATLAB and Origin.